Cramped Home? Attic Trusses Could Be Your Answer

Have you ever looked around your house and wished for just a little more room? Attic trusses can turn that wasted roof space into a cozy bedroom, office, or play area without the headache of full-scale second-story construction.

This post covers attic trusses and why they matter. You’ll see how they compare to traditional roof framing. We’ll break down installation costs, share top design ideas, and explain key building-code requirements.

You’ll also learn when to choose prefab or custom trusses. By the end, you’ll have a clear plan to turn your attic into a usable living space.

What Are Attic Trusses and How Are They Used in Home Construction?

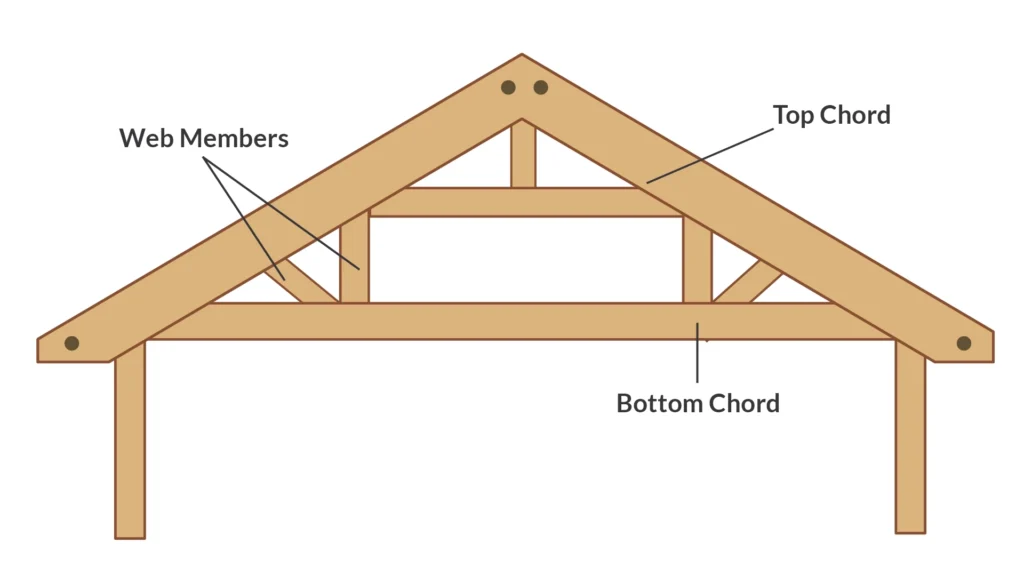

Attic trusses are factory-built roof assemblies engineered with a clear central web section. This design creates open space beneath the roof, allowing you to finish the attic as a bedroom, office, or play area.

Unlike traditional stick framing, where rafters and joists are cut and assembled on-site, attic trusses arrive pre-manufactured to exact specifications, complete with engineered connectors and load ratings.

If you’re not familiar with the basics, check out our detailed guide on what a roof truss is to better understand how different truss systems work.

Because they’re built in a controlled factory environment, attic trusses deliver uniform quality, faster installation, and fewer on-site errors.

Pro Insight: Using factory-built attic trusses can slash your framing time by up to 50 percent compared with stick framing, saving on labor and reducing weather-related delays.

Why does it matter? Attic trusses give you a reliable, efficient way to convert unused roof space into valuable living areas with predictable performance and minimal hassle.

Benefits Of Using Attic Trusses Vs. Traditional Roof Framing

Curious how attic trusses stack up against stick-built roofing? The table below highlights the key advantages so you can choose the best method for your project.

| Aspect | Attic Trusses | Traditional Roof Framing |

| Speed of Construction | Arrive pre-manufactured and can be set in place in hours. | Requires measuring, cutting, and assembling each rafter and joist on site, which can take days. |

| Cost | Higher unit price but lower labor costs and fewer on-site errors. | Lower material cost but higher crew hours and potential delay charges. |

| Structural Consistency | Engineered in a factory with precise metal connector plates for uniform strength. | Field cuts and manual nailing introduce variation and risk of error. |

| Design Flexibility | Custom truss profiles can include dormers or raised heels for extra space. | Stick framing changes require on-site adjustments and may complicate complex shapes. |

| Energy Efficiency | Raised heel trusses allow thicker insulation at the eaves for better thermal performance. | Limited room for insulation at the roof edge can lead to thermal bridges. |

| Quality Assurance | Factory quality control ensures each truss meets exact specifications with minimal waste. | On-site cuts and nails depend on crew skill and can result in inconsistent workmanship. |

| Safety | Fewer roof work hours reduce fall risk and exposure to weather. | Longer roof assembly time increases safety hazards. |

Heads Up: Traditional framing can add several days to your schedule if weather delays occur.

Money Saving Hack: Ordering all your attic trusses at once can unlock volume discounts and reduce shipping fees.

How Much Do Attic Trusses Cost to Install?

Money matters. Before you commit, it helps to understand both material and installation expenses so you can plan your budget without surprises.

Most projects break down roughly like this:

Material Cost (per truss)

Expect to pay between $100 and $400 for each factory-built attic truss. That price covers grade-stamped lumber and precision-pressed metal connector plates. Factors such as the span of your roof, the depth of the truss, and the type of timber you choose will push the cost toward the lower or higher end of that range.

Labor Cost

Professional carpenters typically earn around $29.31 per hour, according to the U.S. Bureau of Labor Statistics. Installation of a single attic truss, including unloading, setting in place, plumb adjustment, and fastening, usually takes between one and two hours. At $25 to $35 per hour in labor, you can expect roughly $25 to $70 in labor costs per truss.

Combined Installed Rate (per square foot)

When you combine materials and labor into an installed rate, most homeowners pay between $5 and $14 per square foot. This all-in number accounts for handling fees, equipment rental, such as a small crane or lift, and any site-specific challenges like roof pitch or hard-to-reach locations.

Heads Up: Costs can climb if you need deeper “raised-heel” trusses to accommodate thick insulation, although those designs often save on long-term energy bills

Attic Truss Design Ideas for Extra Living Space

With the structural frame in place, it’s time to plan how your new attic area will function. Below are three popular layouts that make the most of attic trusses:

Loft Bedroom Retreat

Transform your attic into a peaceful bedroom hideaway. Attic trusses create generous headroom at the center and cozy eaves on the sides. Install a low-sloped ceiling above the bed and add built-in shelving or window seats along the walls.

Quick Idea: Raised-heel truss designs let you add thicker insulation at the roof edge, keeping your bedroom cool in summer and warm in winter.

Home Office Nook

A dedicated work corner fits neatly under a single truss span. Place your desk beneath the peak for maximum ceiling height, and use truss webs as a hidden support for floating shelves or cable channels.

Creative Tip: Install a skylight between truss panels to flood your workspace with daylight without sacrificing wall space.

Playroom with Dormer Trusses

Dormer trusses extend the roof outward, creating vertical walls and windows that add usable floor area. The straight walls simplify installing standard doors and windows, making it perfect for a child’s play zone or a cozy seating spot.

Inspiration: Build a bench under the dormer window and string fairy lights along the truss webs for a magical reading nook.

Each layout leverages the unique geometry of attic trusses to balance headroom, natural light, and storage.

Can Attic Trusses Support a Livable Room?

Yes. Attic trusses are designed to carry the weight of flooring, insulation, and finished walls and ceilings. They typically meet or exceed local code requirements for live loads (people and furniture) and dead loads (building materials).

Key considerations:

- Load Capacity

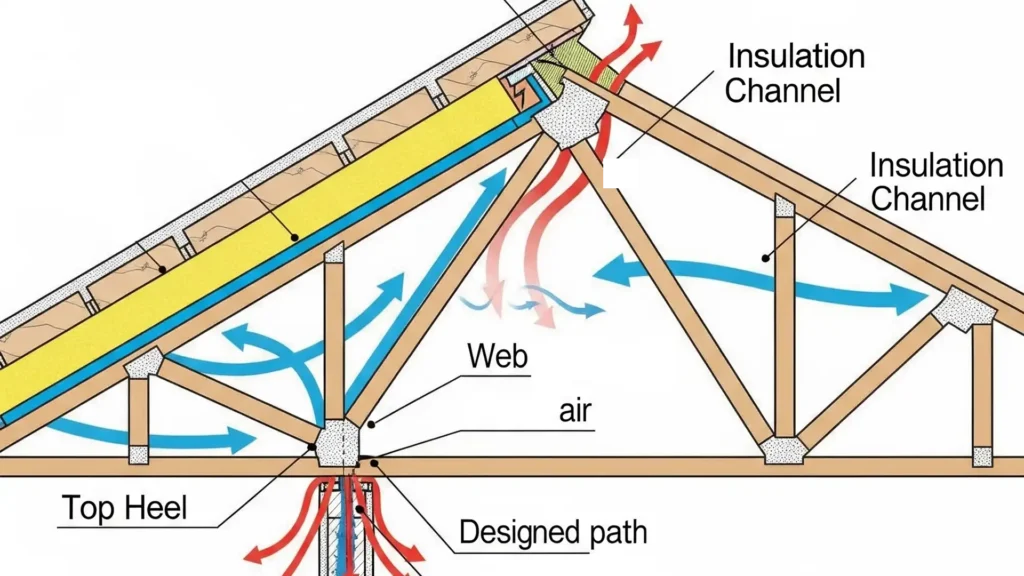

Most attic trusses are rated for live loads of 30 to 40 pounds per square foot and dead loads of 10 to 20 pounds per square foot. Always verify the specific rating on your truss drawings. - Insulation and Ventilation

Proper insulation keeps the room comfortable year-round, while ventilation prevents moisture buildup. Raised heel trusses allow thick insulation at the roof edge and maintain a clear airflow channel above the insulation layer. - Ceiling Heights

Standard attic trusses provide around seven feet of headroom at the center. If you need more height, consider a modified truss profile or a custom design. - Building Codes

Check local requirements for habitable spaces, including minimum ceiling heights and emergency egress. Your engineer or truss manufacturer can supply documentation to satisfy permit inspections.

Quick Idea: Add operable skylights to boost head height and natural light without altering the truss layout.

Building Codes for Attic Trusses with Living Space

Before you finish your attic truss installation, confirm your plans meet local codes for a safe, livable space.

- Attic Truss Permit Requirements

Most jurisdictions require a building permit for any new habitable space created with attic trusses. Be sure to submit your truss manufacturer’s engineered drawings and your finished floor plan to the local building department. - Ceiling Height Standards for Attic Living Space

Codes typically mandate at least seven feet of clear height over half the room area in an attic. Some areas require eight feet for finished attic bedrooms. Check your local rulebook. - Egress Requirements for Attic Bedrooms

Habitable attic rooms must have an emergency exit, usually a window or skylight that meets the minimum opening size and clear path requirements. - Engineered Truss Documentation

Include your truss supplier’s load calculations, installation guides, and live-load ratings with your permit application to demonstrate compliance.

Code Check: Always schedule inspections at the foundation, framing, and final stages to catch any code issues early.

Attic Trusses vs Storage Trusses: Which One to Choose?

When planning your roof framing, it helps to know whether you need full living space capability or simple storage access. Here’s how the two truss types compare:

| Aspect | Attic Trusses | Storage Trusses |

| Intended Use | Designed for finished living areas with full flooring and walls | Built to support light storage only, not habitable spaces |

| Load Capacity | Live loads of 30–40 psf and dead loads of 10–20 psf | Live loads of 10–20 psf and dead loads of 5–10 psf |

| Ceiling Height | Center clear height of around seven feet or more | Often, low eaves and minimal headroom, just enough to walk |

| Insulation Space | Raised-heel options allow thick insulation at the eaves | Limited space for insulation above the storage platform |

| Cost | Higher material and installation costs due to engineered requirements | Lower cost per truss and simpler installation |

| Code Requirements | Must meet all habitable-space codes, including egress and height | Permits may be simpler or not required for storage only |

Quick Idea: If you might convert your storage truss into a living space later, choose a raised-heel storage truss now. It adds insulation, room, and headroom without the full cost of attic trusses.

Which truss best fits your project depends on your long-term goals. For a future bedroom or office, attic trusses pay off. If you only need seasonal storage, a storage truss keeps costs down.

Why Prefabricated Attic Trusses Are Perfect for Fast Home Renovations

Prefabricated attic trusses arrive on site ready to install, cutting your construction timeline dramatically. Since each truss is built in a controlled factory environment, you avoid on-site cutting, fitting, and delays caused by weather or material errors.

Key Advantages:

- Rapid Delivery and Installation

Once you approve the standard truss profile, most suppliers deliver within one to two weeks. Crews can lift and secure each truss in a matter of hours, keeping your project on schedule. - Consistent Quality

Factory assembly under strict quality control ensures every truss meets engineering specifications and load requirements. That consistency translates to fewer callbacks and adjustments. - Lower Design Fees

Standardized truss designs mean you pay minimal or no separate engineering fees. Your cost per unit reflects both the material and the basic profile design.

Quick Idea: Plan your renovation in phases: order all your prefabricated trusses at once to secure volume pricing, then schedule a single delivery to streamline equipment rentals and labor coordination.

Ready to plan your whole roof framing? Head over to our Roof Truss Design Guide for step-by-step layouts, span tables, and code-compliance checklists.

Final Thought

Imagine your attic turned into a bright bedroom or home office instead of wasted space. Engineered attic trusses make that change quick and strong. You get a solid base and the freedom to create a guest room, playroom, or work area that fits your needs.

At Structural Wood Corporation, we make it easy. We work with you to design trusses that match your budget and schedule. We handle all the technical details so you can focus on your new room. Contact us today for a free quote and start planning your dream space.

FAQs

Can Attic Trusses Support A Full Bedroom?

Yes. They are engineered for live loads of 30 to 40 pounds per square foot, which supports flooring, drywall, and furniture. Always check the rating on your truss drawings before finishing the space.

Are Attic Trusses More Expensive Than Stick Framing?

Not necessarily. The per-unit cost may be higher, but you save on labor, reduce mistakes, and speed up your project, which often makes attic trusses more cost-effective.

Do I Need A Building Permit For An Attic Truss Conversion?

Yes. Converting attic trusses into a room requires a permit in most areas. Submit engineered truss drawings, floor plans, and load calculations with your application.

Can I Upgrade Storage Trusses To Attic Trusses Later?

Yes. You can replace storage trusses with living space trusses later. Choosing raised heel storage trusses now adds headroom and insulation space for easier future conversion.

Are Prefabricated Attic Trusses A Good Option For A Fast Renovation?

Yes. Prefab attic trusses arrive ready to install and often ship within two weeks, which means you can avoid on-site cutting and weather delays and complete your renovation faster.