Are you struggling to choose the right gambrel truss for your barn or home?

Picking the right design is crucial for ensuring your roof looks great and stays strong through all kinds of weather. Gambrel trusses offer unique advantages in space and durability, but figuring out the right dimensions, spacing, and construction methods isn’t always easy.

This guide will walk you through everything from gambrel truss dimensions and spacing requirements to framing techniques and practical DIY tips. With this knowledge, you can confidently plan and build a gambrel roof that fits your needs perfectly.

What is a Gambrel Truss?

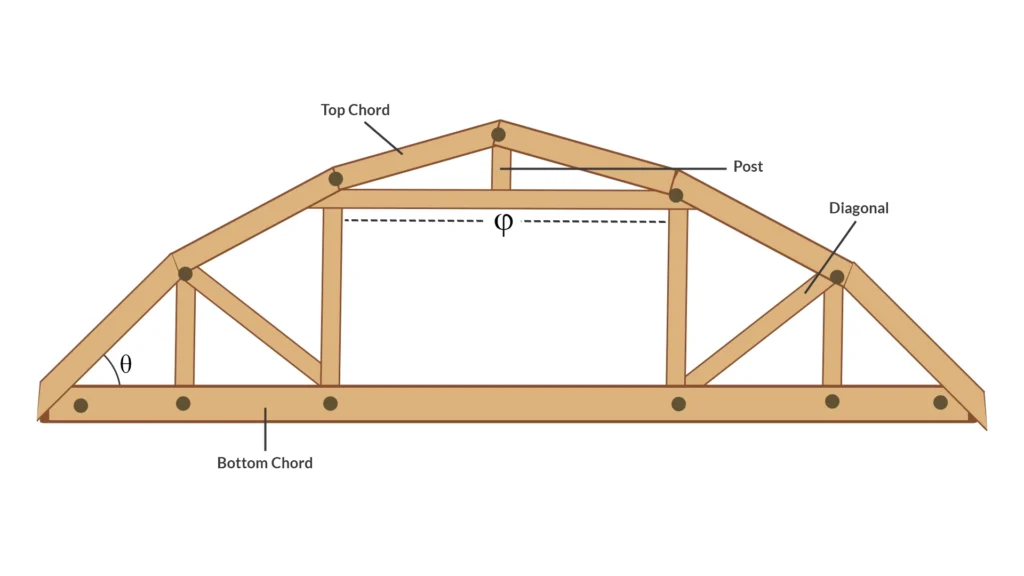

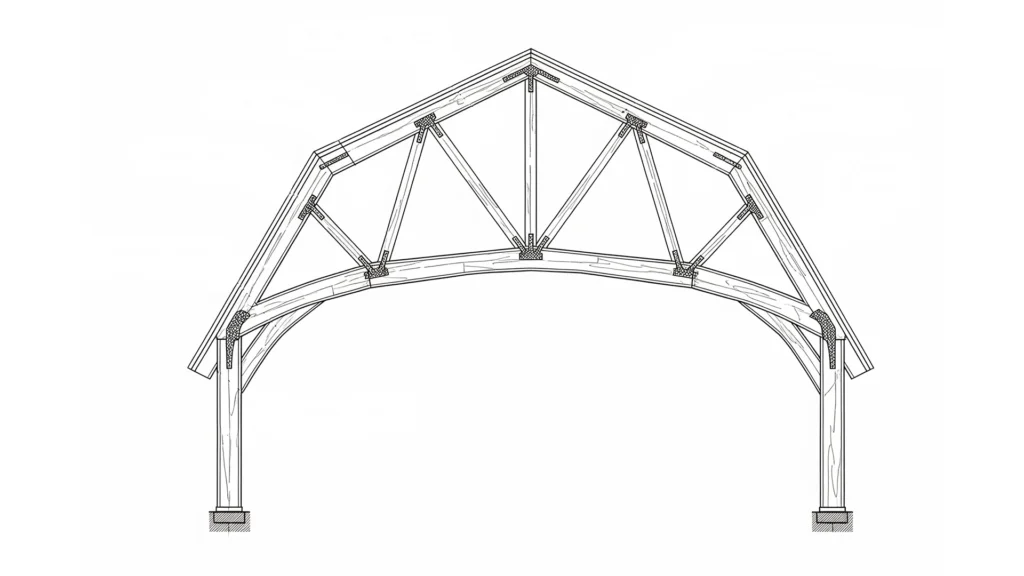

A gambrel truss is a type of roof support structure with two different slopes on each side. The roof structure features a steep lower slope which meets a less steep upper slope. The design of this structure enables additional usable space which makes it suitable for barns and homes with attic rooms.

Why Gambrel Truss? The distinctive design of this truss system provides additional headroom without requiring additional building footprint. The design provides extra space and better ventilation at reduced material expenses.

Tip: Pre-engineered gambrel trusses can save time and ensure consistent quality compared to building from scratch.

Benefits of Gambrel Truss Design

Choosing the right roof truss can greatly affect your building’s function and appearance. The gambrel truss stands out because it offers several advantages, combining practical benefits and aesthetic appeal.

Below are the key benefits that make the gambrel truss design popular for many builders and homeowners.

Maximizes Interior Space

The unique double slope of gambrel trusses creates more headroom in the attic or loft area. This extra space can be used for storage, living areas, or even workshops without increasing your building’s footprint.

Improved Water Runoff

The steep lower slope of gambrel roofs enables quick water and snow runoff, which minimizes the possibility of leaks and water damage over time. The design of gambrel roofs works best in regions with heavy precipitation or snowfall.

Cost Efficiency

Gambrel trusses use materials efficiently by combining strong support with open space, which can lower the overall cost of your roofing project compared to other roof types.

Classic Aesthetic Appeal

With its barn-like silhouette, the gambrel truss adds character and charm to any building. It is often selected for functional and stylistic reasons. This feature has made it popular for residential and agricultural construction.

Versatility in Use

Gambrel trusses adapt well to different building types and sizes, whether for barns, garages, or homes. The adaptable nature of these trusses makes them suitable for numerous construction projects.

Tip: A gambrel truss design is a top choice if you want a versatile roof that offers aesthetic appeal and practical space at the same time.

Gambrel Truss Dimensions and Spacing Requirements

The size and spacing of gambrel trusses depend on your building’s width, the interior space you want, and local building codes. Gambrel trusses are popular for medium to large structures, commonly ranging from 24 feet to over 40 feet in span.

A key design feature of gambrel trusses is the double slope shape. The lower slope is usually steeper and about twice the height of the upper slope. This design helps maximize interior space while keeping the roof structurally balanced.

Materials also influence dimensions and spacing. Wood trusses are common and cost-effective, while steel trusses can span longer distances with fewer supports.

Spacing between gambrel trusses is commonly 24 inches on center for most residential and agricultural roofs, but with engineered designs and specific materials, spacing up to 36 inches or more may be used depending on roof load factors like snow, wind, and roofing weight.

Spacing and dimensions for gambrel trusses vary widely depending on building size and requirements. The table below provides common span lengths and typical spacing ranges to help guide your planning.

| Building Width (ft) | Truss Span (ft) | Typical Spacing (inches) | Notes |

| Up to 24 | 24 | 24 to 36 | Common for small barns or sheds |

| 25 to 36 | 30 to 36 | 24 to 36 | Suitable for medium-sized buildings |

| Over 36 | 40 or more | 24 to 36 | Requires engineered design and approval |

Why does it matter? Proper truss dimensions and spacing ensure your roof can safely support loads without sagging or failure.

Note: Always check local regulations and consult a structural engineer, especially for large or complex buildings, to ensure safety and compliance.

Not sure if your gambrel truss dimensions will hold up under heavy snow or meet local code requirements? Our Roof Truss Design Guide shows you how to calculate spans, load requirements and compliance so you can order the perfect truss with confidence every time.

How to Frame a Gambrel Roof: Step-by-Step Guide

Ever wondered what it takes to put up a gambrel roof? It starts with a solid plan and spot-on framing to capture that iconic two-slope shape. Whether you’re fitting prefabricated trusses or cutting and setting each rafter on site, every single step matters to end up with a roof that is sturdy and built to last.

Below is an explained guide to help you understand the framing process from start to finish.

1. Prepare Your Materials and Tools

Gather high-quality lumber or steel beams, metal connector plates, nails or bolts, saws, measuring tools, and safety equipment. Having everything ready keeps the workflow smooth and efficient.

2. Measure and Mark Your Layout

Ready to get your angles just right? Begin by measuring the full width of your building, then decide how tall you want the steep bottom section and the gentler top section to be. Carefully transfer those numbers onto your boards or work surface—these lines will guide every cut you make.

3. Cut Lumber to Size

Using your measurements, cut the rafters, chords, and supports to the correct lengths and angles. Precision here is vital, as even small errors can affect the truss fit and roof shape.

4. Assemble the Trusses

Join the cut pieces to form the gambrel truss shape. Use metal connector plates or gussets at joints to secure the rafters and chords firmly. Make sure all connections are tight and aligned.

5. Install Temporary Bracing

Add temporary braces during assembly to keep the trusses square and stable. This prevents shifting before the trusses are installed on the building.

6. Lift and Secure Trusses in Place

With help, lift the trusses onto the building frame and space them according to your design (commonly 24 to 36 inches apart). Secure each truss to the top plate with nails or bolts.

7. Secure Your Roof with Permanent Bracing

Install cross braces and collar ties between each truss. These simple additions keep everything from shifting and stop the roof from sagging, so your gambrel stays strong and straight for years.

8. Finish with Decking and Your Roof Covering

Cover the trusses with plywood or oriented strand board sheathing. Roll out an underlayment layer, then add your shingles, metal panels, or other roofing material of your choice. This final step locks in your gambrel shape and makes your roof weatherproof.

Pro Tip: Use a gambrel truss design calculator throughout the process to verify angles, lengths, and load capacity. Accuracy here saves time and money by avoiding costly mistakes.

DIY Gambrel Truss Construction Tips

Building your gambrel truss can save money and give you full control over your roof design.

- Start by carefully measuring your building’s width and desired roof height to calculate the correct gambrel truss dimensions. Use a gambrel truss design calculator or detailed plans to get precise angles and lengths.

- Think of each board as part of a puzzle: measure twice and then cut once so everything fits just right. Fasten every joint with sturdy metal plates or gussets to keep things from shifting. Use top-quality dry lumber or solid steel pieces to make assembly smoother and the finished roof even stronger.

- Never skip your safety gear before you begin. Pull on a pair of heavy-duty gloves, slip on safety goggles, and put on a hard hat to stay protected. Gambrel trusses can be heavy and tricky to handle alone, so having helpers makes lifting and positioning much safer and easier.

- Make sure you have the right tools on hand, such as a circular saw, framing square, measuring tape, clamps, and a nail gun. It’s best to work during dry weather to prevent lumber swelling and slippery conditions.

Common mistakes to avoid include rushing measurements, skipping temporary bracing, or failing to check joints after assembly. Taking your time ensures your trusses are square and strong.

Pro Tip: Take your time during the layout phase. Accurate measurements now prevent costly rework later.

If you are new to roof framing, consider practicing with smaller sections or consulting pre-engineered gambrel truss kits for guidance. Before installation, sand any rough edges to make handling safer and improve the fit.

Gambrel Truss Load Capacity and Span Limits

Gambrel trusses are engineered to support significant loads, including the weight of roofing materials (dead load), snow, wind pressure, and any live load from maintenance or equipment. The overall load capacity depends on several key factors, such as the materials used, truss dimensions, and spacing between individual trusses.

Materials Matter: Timber gambrel trusses are common and cost-effective, but steel trusses can support heavier loads and longer spans. Steel is often chosen for large commercial or industrial buildings needing extra strength.

Understanding Load Types:

- Dead load refers to the permanent weight of roofing components like shingles, sheathing, and insulation.

- The live load includes temporary forces such as snow accumulation, wind, and maintenance workers. Both loads must be carefully considered in the design.

Span Limits Vary: The maximum span of a gambrel truss depends not only on the building’s width but also on the truss depth, the size of chords and webs, and the structural configuration. Typically, timber gambrel trusses can span between 24 to 48 feet without internal supports, but deeper or reinforced trusses may span even further.

Safety Factors: Engineers include safety margins in the design to account for unexpected stresses or environmental changes, ensuring your roof remains stable and secure over time.

Important: Before you start, check your local building codes and engineering guidelines so your gambrel truss can safely handle whatever loads come its way.

Gambrel Roof vs. Gable Roof: Key Differences

Choosing between a gambrel roof and a gable roof can impact your building’s style, space, and cost. The table below highlights the main differences to help you decide which roof type fits your needs best.

| Feature | Gambrel Roof | Gable Roof |

| Roof Shape | Two slopes on each side (steep lower, shallow upper) | Simple triangular shape with two equal slopes |

| Interior Space | Provides more attic or loft space | Less attic space available |

| Construction Complexity | More complex framing due to double slopes | Simpler and quicker to build |

| Aesthetic Appeal | Classic barn style, more unique look | Traditional and widely used |

| Cost | Usually higher due to complexity | Generally more affordable |

| Water Runoff | Steep lower slope aids runoff | Good runoff but less effective than gambrel lower slope |

Keep in Mind: Your choice should balance desired space, budget, and style preferences for the best results.

Cost Considerations for Gambrel Trusses

The cost of gambrel trusses varies based on size, materials, and whether you choose pre-engineered or custom-built options. Pre-engineered gambrel trusses can be more affordable overall because they reduce labor time and waste.

Material choice also affects cost. Timber is commonly used for gambrel trusses due to its cost-effectiveness, while steel options offer greater strength and longevity but usually come at a higher price.

Cost Breakdown (Based on Industry Averages):

- Material Costs: Timber gambrel trusses typically cost $4 to $8 per square foot, while steel gambrel trusses often start at $10+ per square foot due to added strength and complexity.

According to Home Guide, general wood trusses cost $60 to $500 per truss, and steel trusses range from $150 to $700 per truss, depending on size and design.

- Labor Costs: Installation labor varies by location and project complexity, but expect approximately $4 to $10 per square foot.

- Total Project Range: A medium-sized gambrel roof (for a barn or custom home) typically falls between $8,000 and $25,000, but complex projects can reach $30,000+. As noted by HomeAdvisor, roof trusses cost $5 to $14 per square foot installed, depending on material, span, and truss type.

Note: Gambrel trusses are more complex than standard gable or mono trusses. These ranges reflect typical pricing for custom or pre-engineered truss systems in residential or agricultural buildings.

FYI: Getting multiple quotes from suppliers and contractors can help you find the best deal without sacrificing quality.

Maintenance Tips for Gambrel Roofs

Want to keep your gambrel roof looking great and lasting longer? Regular maintenance helps you catch small issues before they turn into costly repairs. Here are the key things to watch for:

- Inspect for Damaged Shingles or Roofing Materials: Look for cracked, missing, or curled shingles that could let water in.

- Check for Water Leaks and Moisture Buildup: Pay attention to any signs of leaks inside your attic or on the ceiling below.

- Clear Gutters and Downspouts: Remove leaves and debris to prevent water overflow that can damage your roof edge.

- Ensure Proper Ventilation: Good airflow reduces moisture and helps prevent mold or wood rot.

- Look for Sagging or Structural Issues: Keep an eye on the roof’s shape and watch for any sagging that might signal weakened trusses.

- Trim Overhanging Branches: Branches touching the roof can cause damage and provide pathways for pests.

- Get an Annual Roof Checkup: A yearly inspection by a trusted roofer can spot hidden wear and tear before it turns into a big headache.

Heads Up: What starts as a tiny leak or loose shingle can become a costly repair if ignored. A little upkeep goes a long way.

Final Thought

A well-designed gambrel truss not only adds valuable attic space and extra strength but also gives your home that classic, eye-catching roofline. By teaming up with skilled professionals and using top-quality materials, you can build a roof that stands strong and lasts for generations.

Ready to take your gambrel roof to the next level? Contact Structural Wood Corporation today for expert advice and high-quality trusses that fit your needs perfectly. Do not wait. Get your free quote now and start building with confidence.

FAQs

How Far Can A Gambrel Truss Span?

Depending on the materials and design, gambrel trusses can typically span between 24 and 48 feet without internal support.

What Materials Are Used For Gambrel Trusses?

Gambrel trusses are commonly made from timber or steel, with steel allowing for longer spans and heavier loads.

How Do Gambrel Trusses Compare To Gable Trusses?

Gambrel trusses provide more usable attic space due to their double slope design, while gable trusses have a simpler triangular shape.

Can I Build My Own Gambrel Truss?

Yes, with accurate measurements, proper tools, and detailed plans, DIY gambrel truss construction is possible, but consulting professionals is recommended for safety.