Do you actually need a girder truss? Here’s how to know

If your roof supports multiple intersecting trusses, spans over 30 feet, or carries a heavy structural load, a girder truss is not optional. It is essential.

Thinking of building a garage, an L-shaped home, or a space with a wide-open layout? If your roof design includes intersecting sections or needs to carry extra weight, a girder truss could be the key element you are missing.

For many builders and homeowners, the biggest mistake happens before construction even begins. Choosing the wrong truss type can lead to sagging roofs, unexpected repairs, and even failed inspections. Standard roof trusses work well for simple spans.

But when your layout gets complex or the load increases, only a girder truss can handle the weight with confidence. Whether you are planning a new residential build or a commercial structure, understanding how girder trusses work will help you avoid costly structural issues and make better design choices.

In this guide, you will learn what makes girder trusses unique, how they are designed, where they are used, how to calculate loads, what materials to choose, and what installation and cost factors to consider.

What Makes a Girder Truss Different?

A girder truss is not your average roof truss. While standard trusses are designed to span from wall to wall and support the roof deck, a girder truss does much more.

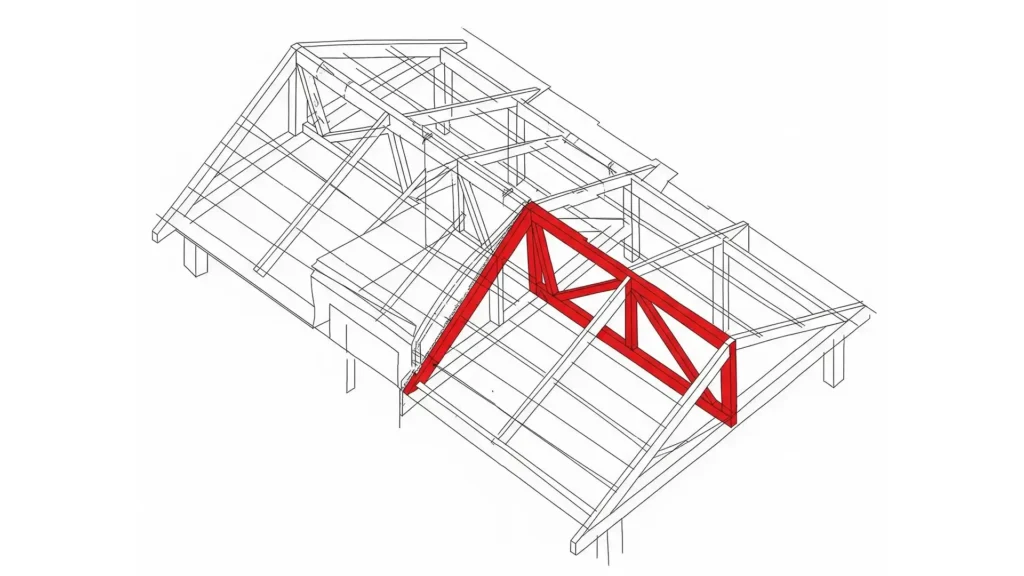

The girder truss acts as a primary structural beam that carries the weight of other trusses connected to it. This makes it one of the most critical components in roofs with complex layouts or heavy load requirements.

The key difference lies in its function. A standard truss only carries its own load. A girder truss carries additional trusses, such as jack trusses or valley trusses, which depend on it for structural support. Because of this, girder trusses are built with larger dimensions, stronger materials, and custom reinforcements.

Did You Know? In many L-shaped or multi-level roof designs, the girder truss is placed at the intersection to act as the main support point. Without it, the structure could shift or fail over time.

Girder Truss vs Standard Roof Truss

To help you understand the difference more clearly, here is a quick side-by-side comparison:

Table: Girder Truss vs Standard Roof Truss

| Feature | Girder Truss | Standard Roof Truss |

| Main Function | Supports additional trusses and heavy loads | Spans between walls to support the roof deck |

| Span Range | Long spans, often over 30 feet | Moderate spans, typically under 30 feet |

| Load Capacity | High load-bearing capability | High load-bearing capability |

| Size and Material | Larger and often custom-built | Precut and standard sizes |

| Common Usage | Garages, L-shaped roofs, and commercial buildings | Single-span residential roofs |

Want to explore how girder trusses compare with other framing styles? Discover more about roof truss types and their best uses.

Reminder: If your roof plan includes valley sections, cross gables, or attached garages, chances are you will need at least one girder truss to support those intersecting trusses safely.

Where Girder Trusses Are Most Useful (With Real Examples)

Girder trusses are not used on every roof. However, when your design steps outside a simple rectangle, it often becomes the most important structural element on the entire frame.

These trusses are used when the load is too great for a standard truss or when the roof design includes complicated shapes and connections.

You will commonly find girder trusses in:

- Attached garages where the roofline breaks away from the main building.

- L-shaped homes are where two truss systems meet at a corner.

- Cross-gable roofs are where different rooflines intersect.

- Large open rooms that require longer spans without internal support.

- Commercial spaces like warehouses or halls demand high-load capacity.

Real World Insight:

In many modern homes, the garage roof connects to the main roof at a different height or angle. Instead of using beams and posts, builders place a girder truss at the connection point. This single truss holds multiple smaller trusses and keeps the entire section aligned, secure, and open underneath.

Understanding Load Requirements Before You Build

Before you can choose or design a girder truss, you need to know how much weight it must carry. This step is non-negotiable. Misjudging the load can lead to sagging, cracking, or even collapse. The load calculation helps you figure out the exact size, spacing, and material your girder truss will need.

Types of Loads You Must Consider

- Dead Load: This includes the weight of the roofing material, ceiling boards, insulation, and the truss itself.

- Live Load: Temporary loads like snow, people walking on the roof, or maintenance equipment.

- Environmental Load: Wind, seismic activity, and even rainfall buildup in some regions.

To estimate the total roof load, add the dead load and live load values (measured in pounds per square foot or psf). Then multiply by the area supported by the girder truss, including any other trusses it is carrying.

Reminder: Even if your truss layout is pre-designed, double-check the local building code. Load requirements can vary by region based on snow, wind, and seismic risk. Always design for the worst-case scenario.

Designing a Girder Truss: Key Specifications You Need to Know

Designing a girder truss is not just about making it thicker or stronger. It requires precise planning that considers the span, load, connections, and roof geometry. Whether you are working with an engineer or ordering a prefab design, these are the core elements to get right.

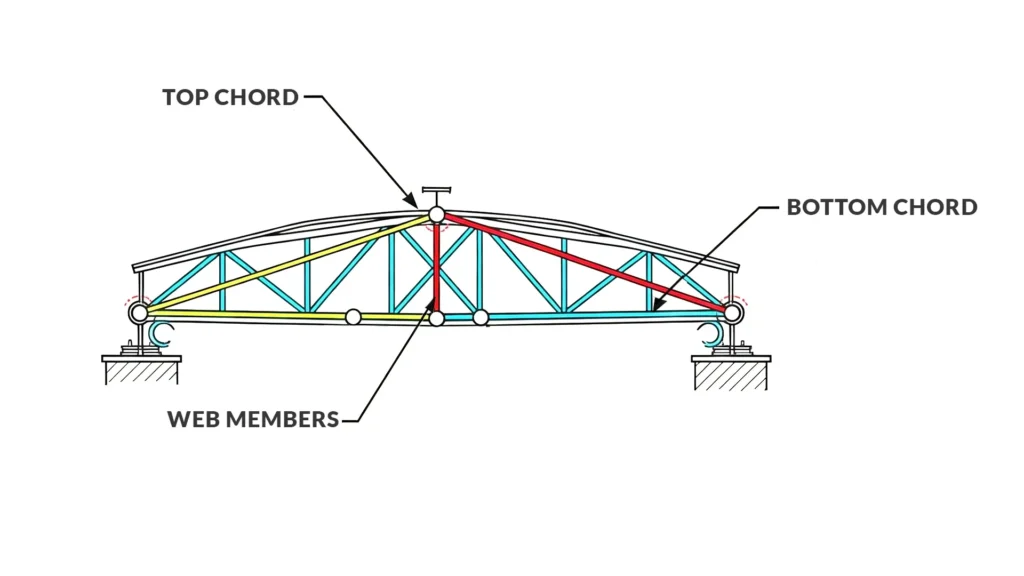

Key Design Considerations

- Span Length: How far the truss must stretch without interior support. Girder trusses often span 30 to 40 feet or more.

- Pitch: The angle of the roof. A steeper pitch changes how the weight is distributed.

- Chord and Web Layout: The top and bottom chords need extra strength. The internal webbing must support the weight of the attached trusses.

- Connection Points: Identify where jack trusses, hip trusses, or valley trusses will connect. These areas must be reinforced.

- Bearing Locations: Girder trusses usually rest on walls or beams. Accurate bearing point placement is critical for balance and safety.

Pro Tip: In homes with intersecting rooflines, the girder truss often becomes a carrier truss, meaning other trusses rest on it. In those cases, work with a structural engineer to ensure it meets both load and safety standards.

Choosing the Right Material: Timber or Steel?

The material you choose for your girder truss affects not just the strength but also the cost, durability, and ease of construction. Most residential projects use timber, while large commercial buildings lean toward steel. But the best choice depends on your span, load, and environment.

When to Choose Timber

- Ideal for residential homes.

- More cost-effective and easier to work with.

- Readily available from local suppliers.

- Suitable for moderate spans and loads.

When to Choose Steel

- Best for long spans or heavy commercial use.

- Resists moisture, fire, and warping.

- Slimmer profiles offer more headroom.

- Often used in factories, showrooms, and industrial spaces.

Material Match Tip: Timber girder trusses are perfect for homes and garages, especially if you want to keep costs low. But if your project is in a high-humidity area or involves large spans with no internal supports, steel offers more strength and a longer lifespan.

Installation Basics: How a Girder Truss Is Put in Place

Installing a girder truss is not just about lifting it into position. Because it often supports other trusses, its placement must be exact, and the entire process requires coordination, precision, and safety checks. One mistake during installation can compromise the entire roof system.

Step-by-Step Overview

- Site Prep and Safety Check

Clear the area, review engineering drawings, and ensure all equipment and bracing tools are ready.

- Hoisting the Truss

Use a crane or mechanical lift to raise the girder truss. Always follow local lifting guidelines and manufacturer instructions.

- Positioning and Bearing

Place the truss directly on the load-bearing walls or beams. Double-check alignment using string lines and a laser level.

- Bracing and Connection

Secure the truss with temporary bracing before attaching the jack or valley trusses. Ensure all bolts, hangers, or nail plates are properly installed.

- Final Inspection

Check for correct spacing, tight connections, and stable bracing before removing any temporary supports.

Safety Check Reminder: Because girder trusses carry extra weight, they must be fully braced before any additional trusses are connected. Installing without proper bracing is one of the leading causes of roof failure during construction.

What Will It Cost to Add a Girder Truss?

The cost of a girder truss can vary depending on the material, span, design complexity, and labor rates in your area. Because it is a high-load structural component, a girder truss is often not only more expensive than standard trusses but also more essential.

Average Cost Breakdown

- Timber Girder Trusses

Typically, it ranges from 300 to 900 dollars per truss, depending on span and timber grade. - Steel Girder Trusses

It often starts at 600 dollars and can go up to 1,200 dollars or more, especially for longer spans or custom-engineered designs. - Installation Labor

Expect to pay 4 to 10 dollars per square foot for professional installation, depending on your location and project needs.

Money Saving Tip: Order your girder trusses as part of a full truss package instead of buying them separately. Many suppliers offer discounts when you purchase from them, along with other components like jack trusses or framing connectors.

Not sure if your girder truss will handle heavy loads or meet local code requirements on complex roof layouts? Our Roof Truss Design Guide shows you how to calculate loads, choose the right materials and ensure compliance so you can order with confidence.

Need Help Sourcing or Designing a Girder Truss?

Choosing the right girder truss can make or break your roofing project. Whether you are working on a new home, a garage addition, or a large commercial space, getting the correct design from the start is the smartest move.

At Structural Wood Corporation, we work with trusted manufacturers and structural experts to help builders source high-quality girder trusses. If you need guidance with design, load calculation, or custom sizing, our team is here to support you with clear answers and fast quotes.

Final Takeaway: Build with Confidence, Not Guesswork

A girder truss is not just another framing component. It is the core support that keeps your roof stable, especially when your design includes intersecting trusses or wide spans. Choosing the right one ensures your structure can handle the weight safely, meet building code requirements, and last for decades without trouble.

If you plan ahead, calculate your loads accurately, and choose the right materials, you will avoid costly repairs and future headaches. Whether you are building a garage, an L-shaped home, or a large open space, the right girder truss will carry the load with strength and reliability.

Final Reminder: A well-designed girder truss is your roof’s strongest link. When in doubt, always consult with professionals who understand both design and structural performance.

FAQs

Is A Girder Truss Necessary For Intersecting Rooflines?

Yes. A girder truss is essential when other trusses connect at angles or intersections. It provides structural support that standard trusses cannot handle alone.

Can A Girder Truss Be Made From Timber?

Yes. Timber is widely used for residential girder trusses. As long as the wood is properly graded and designed for the span and load, it performs reliably.

Does A Girder Truss Cost More Than A Standard Truss?

Yes. A girder truss typically costs more due to its size, custom design, and load-bearing role. However, it replaces the need for extra beams or posts.

Does Every Roof Need A Girder Truss?

No. Only roofs with intersecting layouts, large spans, or heavy loads need a girder truss. Simple rectangular roofs usually rely on standard trusses alone.

Is Special Bracing Required When Installing A Girder Truss?

Yes. Girder trusses carry more weight and must be braced carefully during and after installation to avoid shifting or collapse.