Ever wondered how to build a strong, affordable roof without extra complexity?

Mono truss design could be the answer you need.

This guide will explain what a roof truss is, including the mono truss type and how to plan your span and load capacity. It will also provide easy steps for framing your roof and the top tools to simplify your build. Ready to see how this simple approach can save you time and money?

By the end, you’ll confidently understand how to design and implement a mono truss roof that suits your needs.

What Is a Mono Truss in Roof Construction?

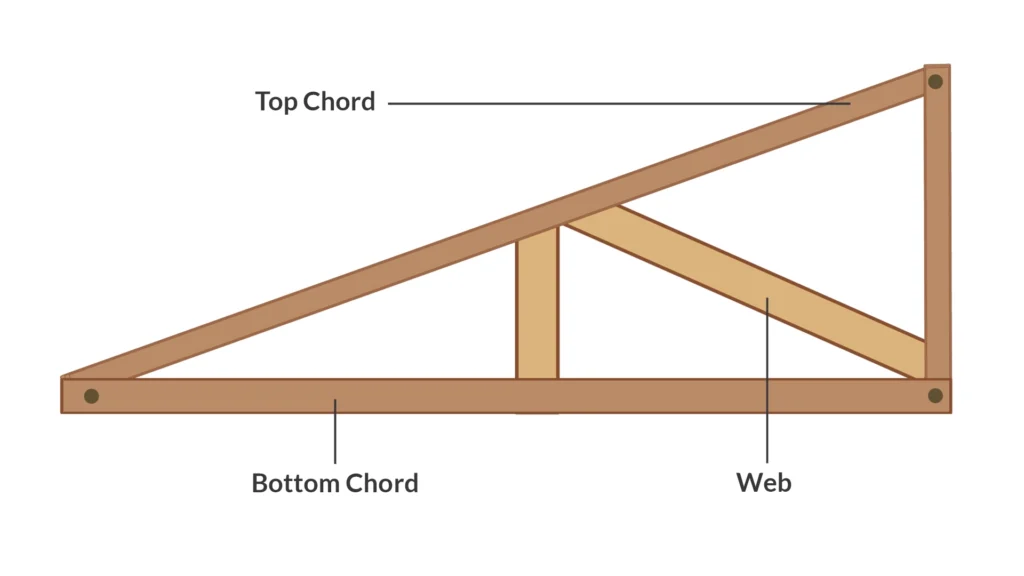

A mono truss is a roof support system with a single sloping surface. Instead of two pitched sides like a gable roof, it uses one top chord that slopes from a high point down to a lower support and a horizontal bottom chord.

With this simple design, you use fewer parts and assemble faster. It also creates a clean, modern look while using less lumber and labor than more complex trusses.

Why it matters: A straightforward design cuts material waste and reduces build time so you can stay on budget and on schedule.

Tip: Check your span early on; knowing the distance between supports helps you pick the right truss dimensions and avoid surprises during installation.

Benefits of Mono Truss Systems

Mono truss design offers clear advantages that make it a smart choice for many roof projects:

Enhanced Interior Space

The single-sloping surface of a mono truss opens up the ceiling area, giving you more usable headroom. That extra height creates an airy atmosphere, making even smaller rooms feel larger and more inviting.

Reduced Material Costs

Because a mono truss has fewer chords and web members than a typical two-slope truss, you use less timber and fewer metal plates. That means lower expenses for lumber and hardware without compromising on strength or durability.

Speedy Installation

With only one surface to build and fewer connection points to secure, assembly goes much faster. Faster installation keeps your project on schedule and can cut days off construction time.

Lower Labor Requirements

With simpler cuts and fewer parts, you don’t need highly skilled builders on site. That cuts your labor costs and means fewer framing mistakes.

Minimal Maintenance Down The Road

Fewer joints and a straightforward design mean fewer potential failure points. Routine inspections become quicker, and any repairs or modifications are simpler.

Note: Together, these advantages help cut down upfront costs and add long-term value by making maintenance and future upgrades simpler. To get even more out of your project, take a look at our roof truss design service. It’s built to save you time, money, and hassle from day one.

Step-by-Step Mono Truss Framing Guide

Feeling overwhelmed by complex roof framing? These seven steps will help you confidently plan, cut, assemble, and install your mono truss.

Step 1: Determine Span and Pitch

- Measure the clear distance between the two wall plates where the truss will sit.

- Decide on the roof slope you need based on local weather and aesthetic preference.

- Calculate the rise over run to establish chord lengths

Tip: A pitch of four in twelve offers good water runoff without extreme angles

Step 2: Select Materials

- Based on span calculations, choose timber grade and size for the top and bottom chords.

- Pick a suitable web member stock for interior bracing.

- Select corrosion-resistant metal connector plates or gussets

Note: Always follow local building codes for timber species and treatment

Step 3: Lay Out Components

- Mark your top chord length and angles using a framing square on a flat, clean surface.

- Transfer web member locations along the top and bottom chords

- Double-check every measurement before cutting.

Warning: Inaccurate layout leads to poor fit and weak joints

Step 4: Cut Chords and Web Members

- Use a circular saw or miter saw to cut chords to exact lengths and angles.

- Cut web members to fit snugly between chords.

- Label each piece to match your layout drawing

Tip: Make trial fits without connector plates to confirm accuracy

Step 5: Assemble on the Jig

- Secure the bottom chord to your workbench or assembly jig.

- Position the top chord and insert web members in their marked locations.

- Fasten connector plates over each joint with a hydraulic press or hammer

Reminder: Keep the assembly flat and square to maintain structural integrity

Step 6: Lift and Brace the Truss

- With at least two people, lift the assembled truss onto the wall plates.

- Temporarily brace each truss side with adjustable support jacks or timber braces.

- Check that the truss is plumb and the slope matches your planned pitch.

Tip: Use a level on both top and bottom chords to ensure accuracy

Step 7: Secure and Tie In

- Fasten truss bearings to wall plates with hurricane ties or approved straps.

- Permanent diagonal bracing between adjacent trusses must be installed for stability.

- Remove temporary braces once all trusses are connected and braced

Note: Proper bracing prevents twisting under wind or snow loads

By following these seven clear steps, you will frame, install, and secure a mono truss that meets design standards while saving time, material, and labor.

Design Considerations for Small Buildings and Garages

Worried a standard roof truss will overwhelm your small build or garage space? These key points will help you get the perfect fit without over-engineering your project.

Span and Support

Smaller buildings often have shorter clear spans but may still need to carry snow or wind loads. Measure the exact distance between supports and confirm your local code requirements for live loads and dead loads. This ensures your mono truss will hold up under real conditions.

Load Capacity Details

Even on a smaller truss, you must account for the weight of the roof covering plus potential snow or water buildup. Calculate the total expected load per square foot and verify that your chosen chord and web member sizes meet or exceed that figure.

Material Selection

For shorter spans, you can often use lighter timber grades or smaller dimension stock without sacrificing strength. Lighter materials reduce cost and make handling components easier on-site.

Before finalizing your design, compare your load calculations against a simple span table from a reputable source to confirm safety.

Note: Skipping this step can lead to costly rework if your truss sags or fails under unexpected loads

Span and Load Capacity Details

How do you know your mono truss will safely carry every load it faces? Start by checking these capacity guidelines based on standard lumber sizes and design loads:

Typical Span Ranges

- Common 2×6 members typically span about 10–12 ft under a 20 psf live load and 10 psf dead load.

- Common 2×8 members span up to 14–16 ft under the same loads.

- Common 2×10 members span up to 18–20 ft, while 2×12 members can reach 22–24 ft or more, depending on species and grade.

Live vs Dead Loads

- Live load covers temporary forces such as snow, maintenance workers, or water buildup (often 20 psf for roofs)

- Dead load covers permanent weight like roofing materials and the truss itself (commonly 10 psf)

Adjusting for Conditions

- If you expect heavier snow or choose tile roofing, raise your live or dead load values. Then check the full span tables for those conditions.

- For example, Table 5802.5.1(1) in the Massachusetts building code lists allowable rafter spans for 20 psf live load and 10 psf dead load across various lumber species and sizes.

Important: Always verify your specific span and load requirements against local building codes and published span tables before finalizing your design. This step is crucial to ensure safety and compliance.

Mono Truss vs Gable Truss

Choosing the right truss type can feel like a guessing game. Here is a quick comparison to help you decide which roof style fits your project best:

| Feature | Mono Truss | Gable Truss |

| Roof shape | One surface slopes from high to low. | Two symmetric surfaces forming a peak |

| Material use | Fewer chords and web members save lumber | More components can increase the material cost |

| Installation speed | Faster with simpler assembly steps | Requires more time for accurate alignment |

| Interior space | Extra headroom on one side | Balanced space under both slopes |

| Water runoff | Good on one side only | Effective on both sides |

| Best for | Single-slope roofs over patios, garages, and sheds. | Classic peaked roofs on homes and barns |

When to choose a mono truss:

- You need a single-slope roof that matches the existing building lines or sheds

- You want faster assembly and lower material costs.

- You prefer extra headroom on one side for clerestory windows or loft storage.

When to choose a gable truss:

- You want a traditional peaked roof with balanced slopes

- You need equal attic space across the structure.

- Your design benefits from a classic roof profile.

Quick Tip: With fewer joints to inspect, a mono truss makes routine maintenance faster and cuts down on unexpected repair headaches.

Steel Mono Truss Standards and Examples

Want to be sure your steel mono truss meets all strength and safety requirements? Here is where to start:

Key Standards: The AISI S100 specification governs cold-formed steel framing design, including roof trusses. The Missouri University of Science and Technology’s library has a detailed guide that breaks down load combinations, member sizing, and connector requirements.

Practical Example: Imagine a carport using a steel mono truss spanning 30 feet. Designers chose 12-gauge cold-formed steel C-sections sized per AISI S100 tables. They used factory-punched connectors for rapid assembly and met all wind and snow load requirements without on-site welding.

Why it matters: Cold-formed steel delivers consistent strength, is lighter than timber, and resists rot or insect damage. Following AISI S100-2007 gives you tested design values and helps streamline fabrication.

Quick Tip: Always have a registered professional engineer review your design against the AISI tables to confirm member sizes and connector details before fabrication.

Top Software For Mono Truss Design Calculations

Looking for a tool to handle the math so you can focus on building? These programs make mono truss design calculations quick and reliable.

SketchUp with Truss Plugin

- Easy 3D modeling and built-in measurement tools

- Free trial available and a large user community for support

Mitek Framework

- Industry standard for automated truss layout and engineering checks

- The cloud-based version lets you generate precise cut lists and connector details.

Autodesk Robot Structural Analysis

- Powerful load simulation for wind, snow, and live loads

- Integrates with Revit for seamless model updates

Why it matters: Using the right software cuts manual errors and speeds up your workflow so you can move from design to build with confidence

Quick Tip: Try the free trials of each program and test its mono truss features, such as automated load checks and cut list generation. Then, compare a sample design report against your local building code requirements to ensure it matches exactly.

Cost-Effective Mono Truss Design for Sheds

Looking to build a sturdy shed roof without overspending? Use these strategies to keep costs down and quality up.

Material Choices

Select standard dimensional lumber such as 2×6 or 2×8 made from locally available softwood. Buying in bulk often earns you volume discounts and reduces delivery fees.

Prefabrication vs On-Site Build

- Prefabricated trusses arrive ready to install, which cuts on-site labor time.

- On-site builds let you avoid shipping wider loads but require more skilled labor.

Optimize Web Layout

Reducing the number of web members in non-critical areas can save timber without affecting strength. Use simple Warren or Pratt web patterns that balance material use with load performance.

Buy Packaged Connector Kits

Pre-assembled plate or bolt kits from a single supplier guarantee compatibility and help you avoid mismatched hardware and excess waste

Quick Tip: Get at least three quotes from truss manufacturers or lumberyards to compare materials, labor, and delivery costs.

Tired of guessing your mono truss span and load specs? Our Roof Truss Design Guide shows you how to determine proper sizes, check load capacities, and meet code requirements so you can order the perfect truss with confidence every time.

Structural Wood Corporation: Your Trusted Truss Partner

Choosing a mono truss design means fewer materials, faster assembly, and lower long-term maintenance. This single slope framework gives you a strong, affordable roof solution that adapts to small buildings, garages, or sheds. With the steps and tips in this guide, you have the knowledge to plan, build, and secure a mono truss roof that meets your needs and budget. Now, it’s time to put these insights into action and watch your new roof take shape with confidence.

At Structural Wood Corporation, we specialize in custom mono truss design and fabrication. Contact us for a free quote or expert consultation to make your next roof project smooth and worry-free.

FAQs

Can I Build A Mono Truss Myself?

Yes. With basic carpentry skills and the step-by-step guide in this article, you can tackle your own mono-truss design project. Just follow local code requirements and safety practices.

What Is The Maximum Span For A Mono Truss?

It depends on lumber size and loads. Standard 2×10 members at 12-inch centers can span about 21 feet under a 20 psf live load and 10 psf dead load. Always verify with your local span tables.

Do I Need An Engineer For Mono Truss Design?

No, for simple, small spans, you can use published span tables. For larger or custom spans, it is wise to involve a registered professional engineer.

How Much Does A Mono Truss Roof Cost?

Costs vary by materials and labor rates. A rough estimate is 20 to 30 percent less than a comparable gable truss roof due to simpler geometry and reduced lumber use.

Is Mono Truss Design Suitable For Heavy Snow Areas?

Yes. By increasing your live load values and choosing heavier grade members, you can adapt your mono truss design to handle heavier snow loads. Always check local building codes for required load ratings.