Have you ever wondered how to bring more natural light into large interior spaces without compromising structure? The answer might lie in the North Light Roof Truss—a time-tested design known for its durability and daylight-maximizing form.

In this article, we’ll walk you through the full details, from design and span advantages to construction and installation tips. Whether you’re designing a factory, warehouse, or even a modern residential project, this guide covers everything you need.

Table of Contents

- What is a North Light Roof Truss?

- North Light Truss Design Explained

- Span and Construction Details

- North Light Roof Truss Installation

- North Light Truss Advantages And Disadvantages

- Common Use Cases

- Environmental Benefits

- Maintenance Tips

- Cost Factors to Consider

- Final Thoughts

- FAQs

What is a North Light Roof Truss?

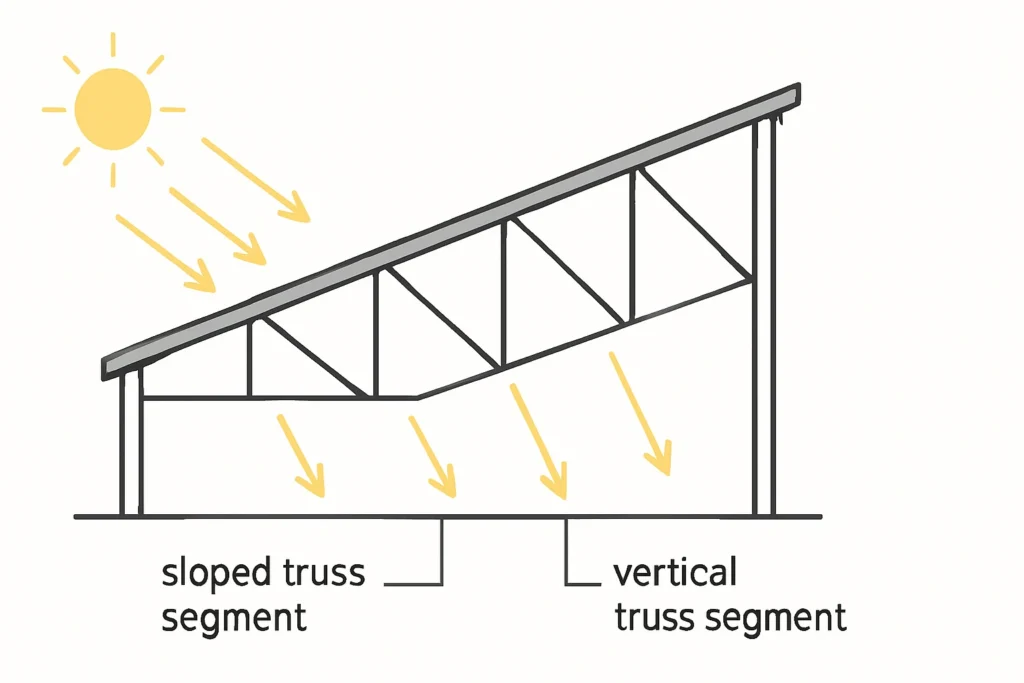

A North Light Roof Truss is a specialized roofing system that combines sloped roof panels with vertical glazed sections. The sloped portions usually face south, while the vertical surfaces are oriented to the north and fitted with glass or translucent materials. This clever design brings in a steady stream of natural light from the north, which is soft and diffused rather than harsh or glaring.

This setup is especially popular in industrial buildings such as factories, warehouses, and workshops, where large interior spaces benefit from consistent daylight without the need for excessive artificial lighting.

Why it matters: North Light Roof Trusses help lower electricity bills by reducing the need for indoor lighting during daytime hours. They also keep the building cooler by minimizing heat gain from direct sunlight, which is especially helpful in warmer climates.

Reminder: This design is most effective in areas where sunlight is stronger from the southern direction. It takes full advantage of natural lighting while avoiding unwanted heat and glare.

North Light Truss Design Explained

The North Light Truss design stands out for its smart use of geometry and natural light. It typically features a repeating pattern of sloped roof sections followed by upright vertical panels. These vertical faces are installed with glazing—usually glass or polycarbonate sheets—that face north to let in soft, diffused daylight.

This design not only brightens up the interior but also supports energy-efficient planning in large buildings. The sloped sections often face south to avoid unwanted glare, while the north-facing glazed parts bring in consistent light throughout the day.

When it comes to materials, the structure can be built using either steel or timber. Steel is often chosen for larger spans and higher load-bearing needs, while timber is more suitable for smaller or medium-scale projects where a lighter frame is preferred.

Tip: Use CAD software to simulate sunlight angles before finalizing your North Light Roof Truss design.

Span and Construction Details

One of the most important aspects of a North Light Roof Truss is how far it can span. In most cases, the span ranges between six to sixteen meters. This depends largely on the materials used and the overall structural design. When steel is used as the primary material, the trusses can extend even farther—up to twenty meters in some cases—without compromising strength.

To get the most benefit from this design, trusses are carefully spaced apart. The goal is to allow as much natural light in as possible while keeping the entire structure stable and safe. If you space the trusses too far apart or try to stretch the span beyond its limits without proper reinforcement, the result could be structural sagging or even buckling over time.

Important: Always make sure your span and truss spacing are checked by a structural engineer. Extending spans without proper support is risky and can lead to long-term safety issues.

Note: Your final design should also take into account local wind loads, snow loads, and roof pitch requirements. These building code factors vary by location and have a direct impact on how your truss system should be constructed.

North Light Roof Truss Installation

The installation of the North Light Roof Truss demands precise planning and sequential execution to achieve both safety and operational functionality. The following section describes the standard installation process that modern construction projects use:

Step 1: Prepare the foundation and lay out the columns

The first step requires proper leveling and marking of the foundation. The procedure requires engineers to position columns exactly as shown in drawings to achieve correct alignment and load distribution.

Step 2: Prefabricate the trusses off-site

The construction of trusses should occur in a controlled environment before their transportation to the construction site whenever possible. The use of steel trusses requires this recommendation. The prefabrication process decreases mistakes while reducing waste materials and shortening the overall construction duration.

Step 3: Erect the columns and place the truss members

The truss members receive sequential placement after the columns reach their correct positions. The frame requires precise placement to achieve secure assembly.

Step 4: Install purlins and roofing sheets

With the trusses secured, purlins are added across the top to support the roof covering. Once those are installed, roofing sheets are attached to complete the upper layer of the structure.

Step 5: Fix the glazing on the north-facing vertical surfaces

The final step involves attaching the glazing panels. The north-facing transparent or translucent sections will enable natural daylight to enter the interior space.

The construction process becomes faster through off-site truss prefabrication while achieving better precision. The construction process benefits from this method because it minimizes installation mistakes and reduces the need for expensive adjustments during construction.

Warning: Always prioritize safety. When working at height during truss placement, proper scaffolding and safety harnesses are a must. Do not allow shortcuts, even for small jobs.

North Light Truss Advantages And Disadvantages

Before choosing a North Light Roof Truss, it helps to weigh the benefits against the limitations. This system offers outstanding lighting and energy savings, especially in large industrial settings. However, it may not be the best fit for every project due to its design complexity and cost.

| Advantages | Disadvantages |

| Allows excellent natural light to enter evenly throughout the interior | The design process is more complex and may require expert input |

| Reduces dependency on artificial lighting, helping lower energy bills | Initial construction costs are higher due to materials like glazing |

| Supports good airflow and ventilation when combined with roof vents | It may not be practical or cost-effective for small-scale residential buildings |

| Perfect for wide-span structures like factories, studios, and industrial sheds | Installation requires skilled labor and precision planning |

Tip: If your project values long-term energy savings and natural lighting, the investment in a North Light system often pays off over time.

Common Use Cases

Here are a few specific industries where the North Light Roof Truss truly shines:

- Textile manufacturing units where bright natural light helps with visual accuracy

- Printing and packaging plants that rely on consistent daylight

- Food processing facilities that benefit from improved ventilation and lower lighting costs

- Art studios and design workshops where soft light is preferred over artificial sources

These trusses are especially effective in spaces where tasks require attention to detail, color accuracy, and reduced energy load.

Environmental Benefits

A North Light Roof Truss is more than just a smart design choice—it is also environmentally responsible. Reducing the need for artificial lighting during the day cuts down on electricity use, which lowers your building’s overall carbon footprint. This design may also contribute to sustainability certifications such as LEED or NABERS, depending on your region.

Reminder: Less heat from direct sunlight means your air conditioning system does not need to work as hard, resulting in even more energy savings.

Maintenance Tips

Keeping your North Light system in good shape requires some basic care. Here are simple tips to help:

| Task | Frequency | Tools | DIY-Friendly |

| Clean glazed surfaces | Every 3–6 months | Soft cloth, mild soap | Yes |

| Inspect for cracks or leaks | Every 6 months | Flashlight, sealant | Yes |

| Check for rust or corrosion | Annually | Wire brush, primer | Yes |

| Verify truss connections | Annually | Wrench, inspection kit | No (use pro) |

Tip: Regular inspections help avoid long-term issues and maintain structural safety.

Cost Factors to Consider

While North Light systems can be more expensive up front, understanding the cost drivers can help with better planning:

- Glazing material: High-quality polycarbonate or glass panels increase initial costs but improve performance

- Span length: Larger spans require more structural support, especially in steel

- Labor and engineering: Complex designs require precise planning and experienced installation crews

- Prefabrication: Though it has an initial setup cost, it often reduces on-site labor and speeds up timelines

Reminder: The savings from electricity consumption and enhanced lighting quality will eventually offset the initial investment costs.

Final Thoughts

The North Light Roof Truss selection creates structural support while generating a brighter and more energy-efficient space. This system provides a dependable method to boost natural lighting while decreasing electricity consumption and enhancing building operational efficiency.

While the design and setup may require careful planning, the long-term rewards are well worth it, especially for larger industrial or commercial buildings.

Always make sure your design is validated by a professional engineer. All measurements, load calculations, and spans need to follow structural safety standards to prevent future costly problems.

At Structural Wood, we create durable truss systems that match the specific requirements of each project. We are always ready to assist you in finding the most suitable solutions for your objectives, whether you are beginning a new construction project or enhancing an existing one.

Need expert guidance? Let us take a look at your site and provide a free consultation to help you make the right decision from the start.

FAQs

What is a North Light Truss?

Yes, it is a type of roof truss that includes vertical glazed sections facing north. This design allows soft and consistent daylight to enter the space without causing glare.

How far can a North Light Roof Truss span?

Most North Light trusses span between six and sixteen meters. However, when built with steel, they can reach up to twenty meters, depending on the structure.

Is this system suitable for residential homes?

Not really. It is best suited for industrial or commercial buildings that need wide, well-lit spaces, such as factories or studios.

Can timber be used instead of steel for this truss?

Yes, you can use timber for smaller spans. But for larger or heavier loads, steel is usually the more reliable option.

What are some of the downsides of using this truss?

The design can be complex, and the initial costs are higher, mainly due to materials like glazing and the need for precise engineering.