Is the Pratt Roof Truss Still the Best Choice in 2025?

Absolutely. When engineered correctly, the Pratt truss remains one of the most reliable and cost-efficient roof framing systems, especially for medium to long-span structures.

But what makes it stand out? Why do builders, architects, and engineers continue to trust it over newer or trendier alternatives? And how does it stack up against other popular designs like the Howe or Warren truss?

Whether you’re planning a new construction project or simply want to understand the basics, this guide will walk you through everything you need to know.

From core design principles and structural formulas to helpful charts, dimension guidelines, and common installation issues, we cover it all in one place.

Let us take a closer look and find out why the Pratt truss still holds its ground in modern construction.

Table of Contents

| 1. | What Is a Pratt Roof Truss? |

| 2. | How Pratt Truss Design Works |

| 3. | Pratt Roof Truss Dimensions and Charts |

| 4. | Pratt Truss Design Formula and Calculator |

| 5. | Types of Pratt Roof Trusses |

| 6. | Common Problems and Fixes |

| 7. | Maintenance Checklist |

| 8. | Is Pratt or Howe Truss Better? |

| 9. | Conclusion |

| 10. | FAQs |

What Is a Pratt Roof Truss?

A Pratt roof truss is a structural framework made of vertical and diagonal members designed to support roof loads effectively. In this system, the diagonal members are placed to handle tension, while the vertical members take on compression. This combination helps distribute weight evenly across the span.

The design works best for spans between 6 to 30 meters and is widely used in industrial, commercial, and large residential buildings.

Why does it matter? It offers a strong balance of strength and efficiency. The Pratt truss uses less material, is simple to build, and performs reliably under heavy roof loads, which makes it a favorite among builders and engineers.

Tip: A properly engineered Pratt truss reduces material waste by over 20% compared to irregular framing systems.

How Pratt Truss Design Works

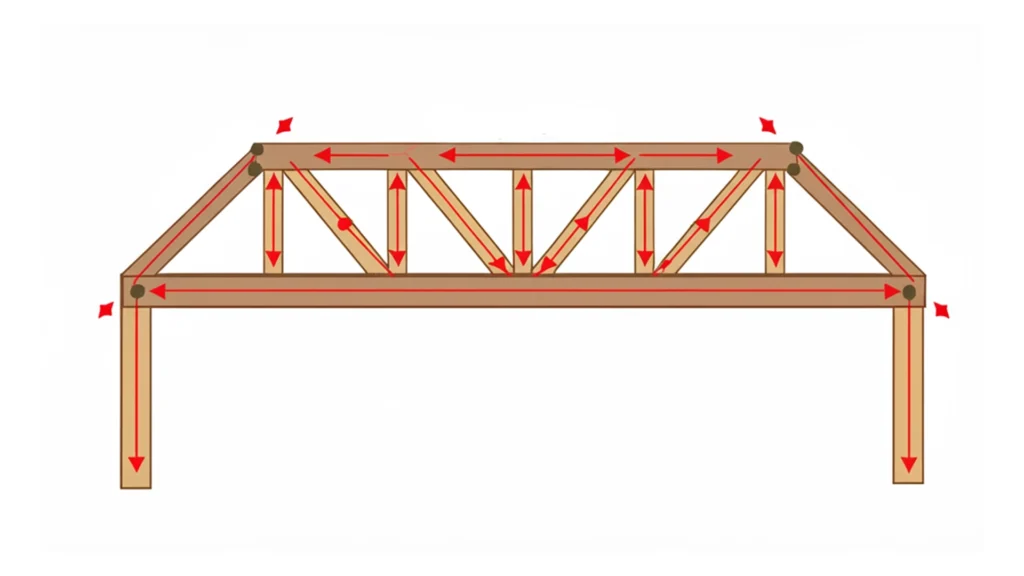

The Pratt truss design is built on a simple but effective concept: let each member of the structure do what it does best. Here’s how the load path works:

- The diagonal members point downward toward the center of the span. These are placed to carry tension, which means they are being pulled rather than pushed.

- The vertical members handle compression, absorbing the weight that pushes down from the roof and transferring it safely to the supports.

- The top and bottom chords work together to resist bending. The top chord is usually under compression, while the bottom chord stays in tension, helping the entire truss maintain its shape.

Why does it work so well? By placing tension in the diagonals and compression in the verticals, the structure becomes both lightweight and highly stable. Tension members can be thinner and less expensive, while the few compressive elements remain strong with very little bracing. This balance is what makes the Pratt truss not only efficient but also economical and easy to adapt to various building needs.

Note: The design performs best when the loading is symmetrical.

Pratt Roof Truss Dimensions and Charts

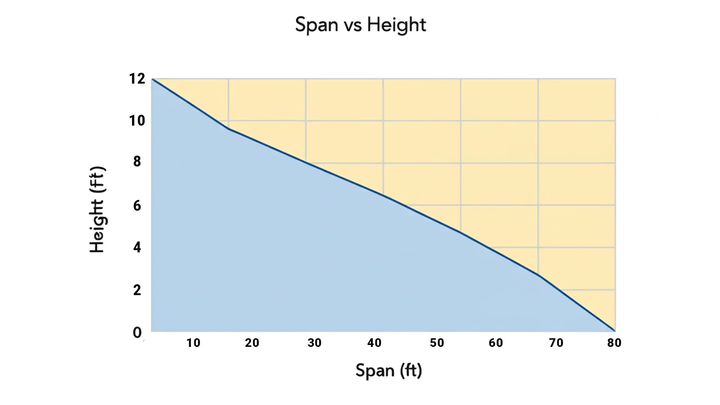

The design of Pratt trusses depends on established ratios which guarantee structural strength and stability and maximize material efficiency. Standard designs follow predictable measurement ranges which depend on building type and load requirements.

Here is a general guideline:

| Span (ft) | Height (ft) | Panel Length (ft) | No. of Panels |

| 20–30 | 4–6 | 4–5 | 4–6 |

| 30–50 | 6–9 | 5–6 | 6–8 |

| 50–80 | 9–12 | 6–8 | 8–10 |

These standard dimensions make it easier to plan materials, estimate load capacity, and streamline the manufacturing or prefabrication process.

Reminder: The total height is usually 1/5 to 1/6 of the total span.

Pratt Truss Design Formula and Calculator

To understand how a Pratt roof truss handles weight, you can start with a basic structural formula. This equation gives a rough estimate of the bending moment, which helps determine how the truss will react under uniform loads.

M = (w × L²) / 8

Where:

- M is the maximum moment

- W is the uniform load per unit length

- L is the length of the span.

This formula gives you a simple way to estimate how force is distributed across the structure. It works best for basic, evenly loaded trusses and should not be used alone for final decisions.

For more accurate results, use a Pratt roof truss design calculator such as SkyCiv, EngineeringToolBox, or your preferred CAD software. These tools let you adjust for live loads, material type, spacing, and custom geometries.

Important: This formula provides a rough estimate for evenly distributed loads and simple spans. For complex conditions or final designs, always consult a structural engineer and use detailed design software.

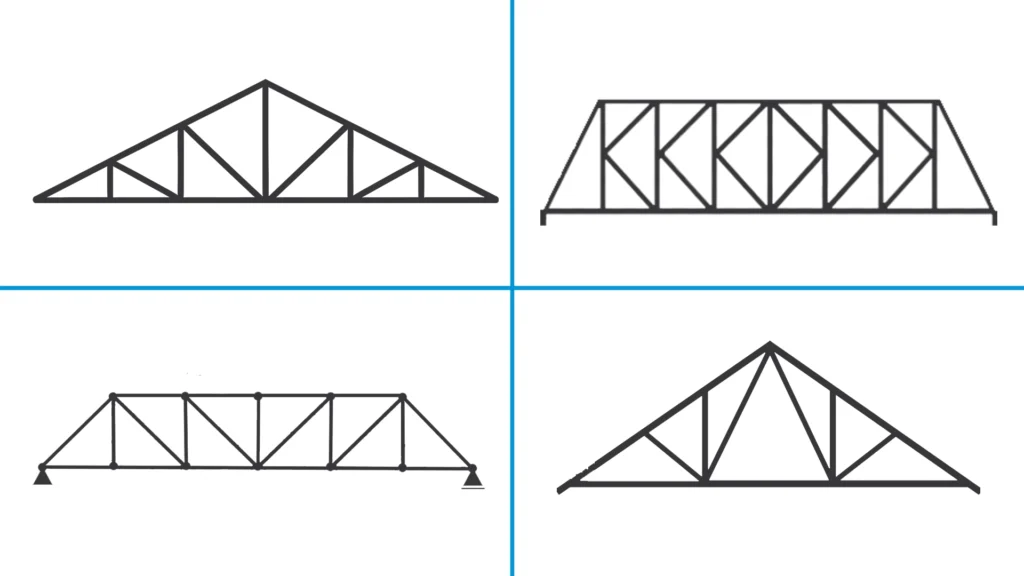

Types of Pratt Roof Trusses

While the basic Pratt truss design is widely used, there are several variations that offer added strength, flexibility, or adaptability for different building needs. Choosing the right type depends on your span, load conditions, and roof shape.

Standard Pratt

This is the most common version, ideal for medium-span structures such as warehouses, halls, and light industrial buildings. It provides reliable strength with a simple layout that is easy to fabricate and install.

Modified Pratt

Built to handle heavier loads, this version includes additional bracing or thicker members. It is used in situations where roof systems must support more weight or resist stronger environmental forces like snow or wind.

Double Pitch Pratt

This variation features sloped top chords, making it suitable for buildings with uneven rooflines or where drainage and aesthetic design are key. It also adapts well to structures with asymmetrical loads.

Fan Pratt

Designed for longer spans that require multiple panels, the Fan Pratt breaks the load into smaller sections. This reduces stress on individual members and allows for a more even distribution of weight across the truss.

Tip: Always match the truss type to your building’s span, load requirements, and architectural layout to get the most efficient design.

Common Problems and Fixes

Even though Pratt roof trusses are strong and dependable, they can still face problems if they are not built or maintained properly. Here are some common issues and how to fix them:

1. Too Much Weight

- Cause: If the roof carries more weight than it was designed for, parts of the truss can bend or fail.

- Fix: Remove some of the load or add extra support pieces to help share the weight.

2. Damage from Strong Winds

- Cause: Without proper wind bracing or strong joints, high winds can shake or lift the truss.

- Fix: Add wind bracing, use hurricane ties, and make sure all connections are secure and tight.

3. Rotting or Rusting Materials

- Cause: Over time, wood can rot, or metal can rust if exposed to moisture or pests.

- Fix: Replace damaged parts, treat wood with protective coatings, and improve ventilation to keep things dry.

4. Weak or Loose Connections

- Cause: Joints between parts of the truss can loosen over time or if installed incorrectly.

- Fix: Add bolts, brackets, or plates to strengthen the connections, and check them regularly.

5. Bending or Buckling

- Cause: Some parts of the truss can bend if they are too thin or not supported well.

- Fix: Use thicker pieces or add bracing to keep the parts straight and strong.

Maintenance Checklist of Pratt Roof Truss Design

Regular maintenance keeps a Pratt roof truss strong and reliable. Even small issues like rust, loose fasteners, or weak bracing can lead to bigger problems if ignored.

This quick checklist shows what to check, how often, and what tools you need to keep everything in good shape.

| Task | Frequency | Tools Needed | DIY-Friendly |

| Check for rust or rot | Every 6 months | Flashlight, ladder | Yes |

| Inspect for sagging or bowing | Every 6 months | Visual check | Yes |

| Tighten fasteners | Annually | Wrench, torque meter | Yes |

| Replace damaged bracing | As needed | Hammer, nails, replacement parts | No |

Reminder: If you notice cracks, sagging, or unusual movement, have a structural expert check it before it gets worse.

Is Pratt or Howe Truss Better?

The answer depends on one important factor: the direction of the load.

A Pratt truss works best when the load comes from above, such as in roofing. Its diagonal members are placed to carry tension, while the vertical members handle compression. This setup makes it highly efficient for supporting roof weight without adding unnecessary bulk.

According to the Federal Highway Administration, this design originally used metal rods in the diagonals to manage tension and timber posts to carry compression, a combination that made it strong and materially efficient.

On the other hand, the Howe truss is better suited for loads that come from below, which is why it is often used in bridge construction. In this design, the roles are reversed. The diagonal members are under compression, and the vertical members carry tension.

The same FHWA study notes that Howe trusses used vertical metal rods for tension and wood diagonals for compression, showing a clear contrast in how the two systems manage forces.

In short, for roof systems, the Pratt truss is the better option. It handles downward loads more efficiently, uses fewer materials, and simplifies construction without compromising strength.

Not sure if the Pratt truss will meet your span or load requirements? Our Roof Truss Design Guide helps you evaluate span limits, material choices, and code compliance so you can order the perfect truss with confidence every time.

Conclusion

A Pratt roof truss design remains one of the smartest choices for modern construction. It combines efficient material use, simple geometry, and flexibility with both timber and steel. This design continues to deliver long-lasting performance while keeping structural costs in check.

With the right charts, dimensions, and calculator, you can plan a safe and stable structure that holds strong for decades. Always check your design through trusted engineering tools or seek advice from a qualified expert to prevent costly errors.

At Structural Wood Corporation, we support builders and architects in creating high-performing truss systems that meet both design goals and budget expectations. Whether you need a detailed Pratt truss drawing or a custom quote, our team is ready to help you bring your vision to life with confidence.

FAQs

What are the three disadvantages of a Pratt truss?

The main disadvantages include limited use in asymmetrical loading, increased tension joints, and higher deflection under strong wind loads.

Is the Pratt truss strong?

Yes, the Pratt roof truss design is known for its strength and reliability. It performs especially well under vertical loads and is suitable for long spans when properly engineered.

Is a Pratt or Howe Truss better?

For roof applications, the Pratt truss is generally the better option. It handles downward loads more efficiently, while the Howe truss is more suitable for bridge structures with upward force conditions.

Where can I find a Pratt truss design example?

You can explore design platforms like SkyCiv or download standard CAD files online that show common Pratt truss layouts and dimensions.

Can I design a Pratt truss with online calculators?

Yes, tools like SkyCiv, EngineeringToolBox, and other design calculators can help you run basic load analysis using the Pratt roof truss design formula. For final designs, always verify with a structural engineer.